Paint protection for commercial vehicles & buses

In the commercial vehicle and bus sector, we specialize in applications where heat resistance, resistance to heavy mechanical loads, strong corrosion protection and extensive chemical resistance are required. Decorative outer skin coatings are also offered in the commercial vehicle sector. Our product portfolio consists exclusively of liquid coating systems.

WE ALSO OFFER INDIVIDUAL DEVELOPMENTS

Not found the right product – Looking for a solution to a specific problem? As a partner with many years of experience, we work with you to develop customized solutions for your application.

Paint protection for the outer skin of fuel tanks

Protection against stone chipping and chemical resistance are required here.

Layer thicknesses of up to 500 µm are possible.

Stone impact resistance test according to DIN EN ISO 20567-1:2007 procedure B up to 20kg.

With a maximum permissible infiltration of 2 mm after 504 h Neutral salt spray test NSS

Paint protection for brake systems, brake discs, brake drums

Stone impact

Stone impact resistance test: DIN EN ISO 20567-1:2007, method B up to 2 kg

Corrosion protection

We now have paint systems that offer heat resistance up to 1000°C

Neutral salt spray test NSS DIN EN ISO 9227

Heat resistance

1,000 °C or up to 650 °C with a load of up to 2 h

Exhaust systems

Heat-resistant and extremely low smoke development when exposed to heat

up to 1,000°C

Stone chip protection

Corrosion protection

Paint protection for drive components Cardan drive and side shafts

Corrosion protection and mechanical resistance according to the specifications of the automotive industry

Rockfall

Stone impact resistance test: DIN EN ISO 20567-1:2007, method B up to 2 kg

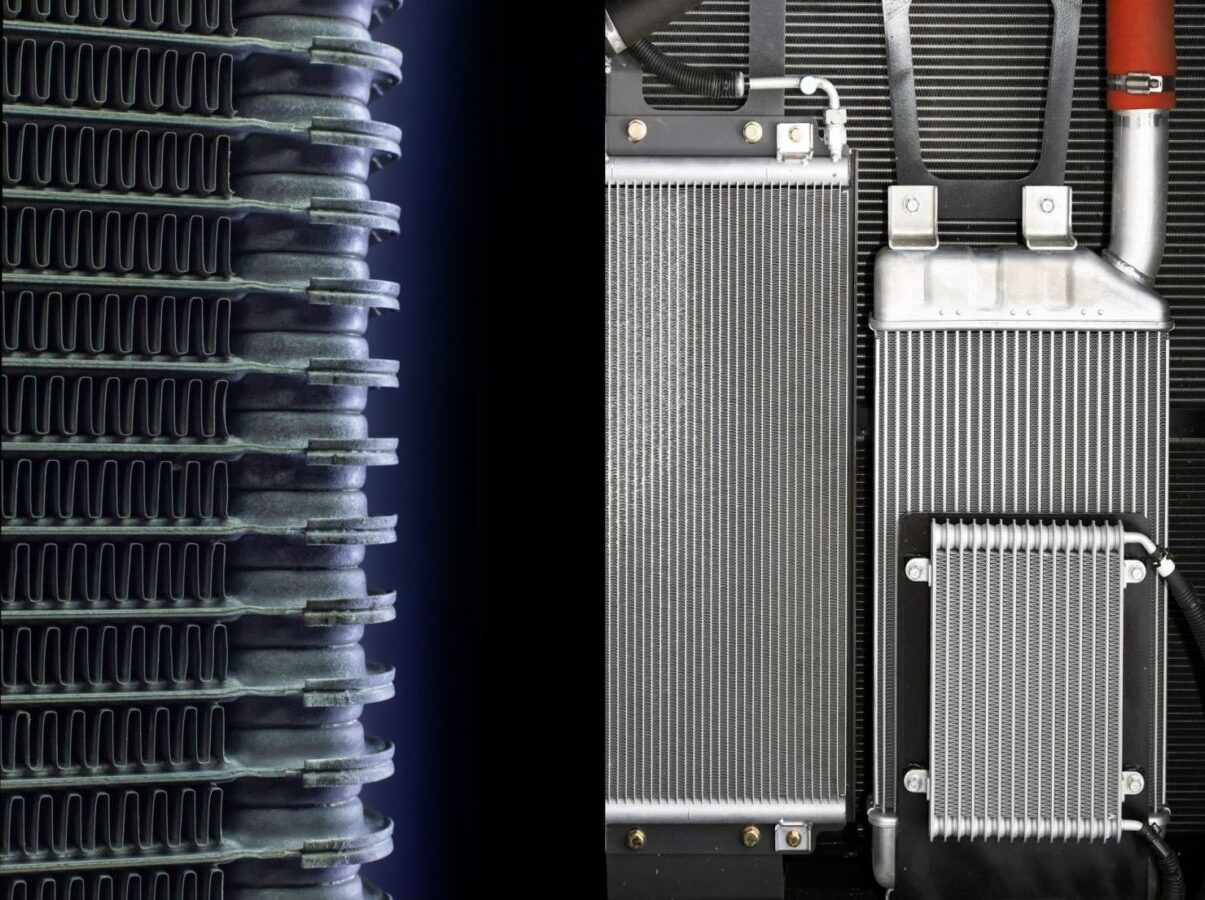

Paint protection for cooling and air conditioning

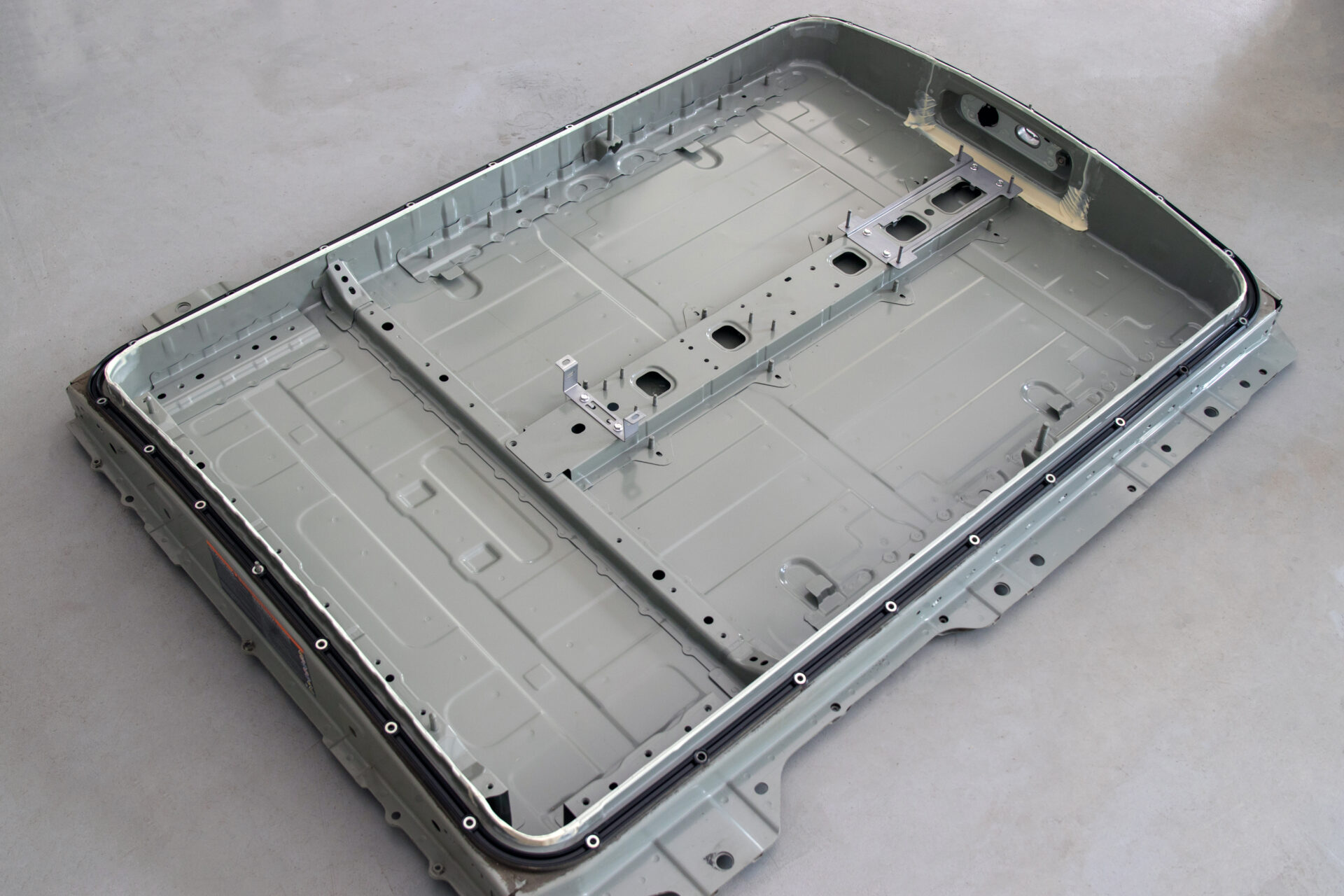

Paint protection in the e-mobility sector Battery housings and covers

For this new segment, paint systems are offered that can withstand heat loads of up to 1,000°C. The dielectric strength on the test panels reached values of

of 1250V (unloaded) and 1150V (after 10 min 900°C heat-loaded)

Paint protection for the underbody

Stone chip protection test