Paint protection and design for

the automotive sector

We are YOUR specialist for automotive paint systems.

Our focus in the development of new coating systems is on:

– Resistance to mechanical stress

– Chemical resistance

– Heat resistance

– Corrosion protection

– Stone chip protection

The majority of our products used in the automotive sector are liquid coating systems.

Request non-binding advice now

We also offer individual developments

Are you looking for a solution to a specific problem? As a partner with many years of experience, we work with you to develop customized solutions for your application.

Paint protection for the outer skin of fuel tanks

Protection against stone chipping and chemical resistance are required here.

Layer thicknesses of up to 500 µm are possible.

Stone impact resistance test according to DIN EN ISO 20567-1:2007 procedure B up to 20kg.

With a maximum permissible infiltration of 2 mm after 504 h Neutral salt spray test NSS

Paint protection for brake systems, brake discs, brake drums and fine dust filter systems

Stone impact

Stone impact resistance test: DIN EN ISO 20567-1:2007, method B up to 2 kg

Corrosion protection Corrosion cycle test up to 30 cycles. Layer thicknesses of up to 120 µm are possible

Neutral salt spray test NSS DIN EN ISO 9227

Test duration: 240h

Heat resistance

1,000 °C or up to 650 °C with a load of up to 2 h

Paint protection for exhaust system tailpipes and heat-exposed add-on parts

Heat-resistant and extremely low smoke development when exposed to heat

Heat resistance up to 1,000°C

Rockfall

Corrosion protection

Paint protection for plastic and carbon coatings and carbon rims

UV stability

Heat-resistant up to 220°C

Mechanically and chemically resilient

Paint protection for drive components

Cardan drive and

Side shafts

as well as steering systems.

Corrosion protection and mechanical resistance according to the specifications of the automotive industry.

Rockfall

Stone impact resistance test: DIN EN ISO 20567-1:2007, method B up to 2 kg

Paint protection for e-mobility Battery management

For this new segment, paint systems are offered that can withstand heat loads of up to 1,000°C.

The dielectric strength on the test panels reached values of 4800 V (unloaded) and 1150 V (after 10 min 900°C heat load)

Paint protection for chassis, axle carriers and add-on components

In many cases, the obilgatory CDP coating is no longer sufficient. For additional protection against stone chipping, we offer systems that allow a coating thickness of up to 500 µm and provide excellent corrosion protection together with the CDP coatings available on the market.

Our latest development, our ERS system, offers extremely fast drying at room temperature and also with unfavorable drying parameters.

Chemically resistant

Corrosion protection

Functional and decorative exterior-interior components

Trim strips

Roof railing

Sill

Parking and distance sensors

Tailpipe trims

Chassis protective coating systems

Spoiler

Head-up displays

Center console

Cladding – and fittings

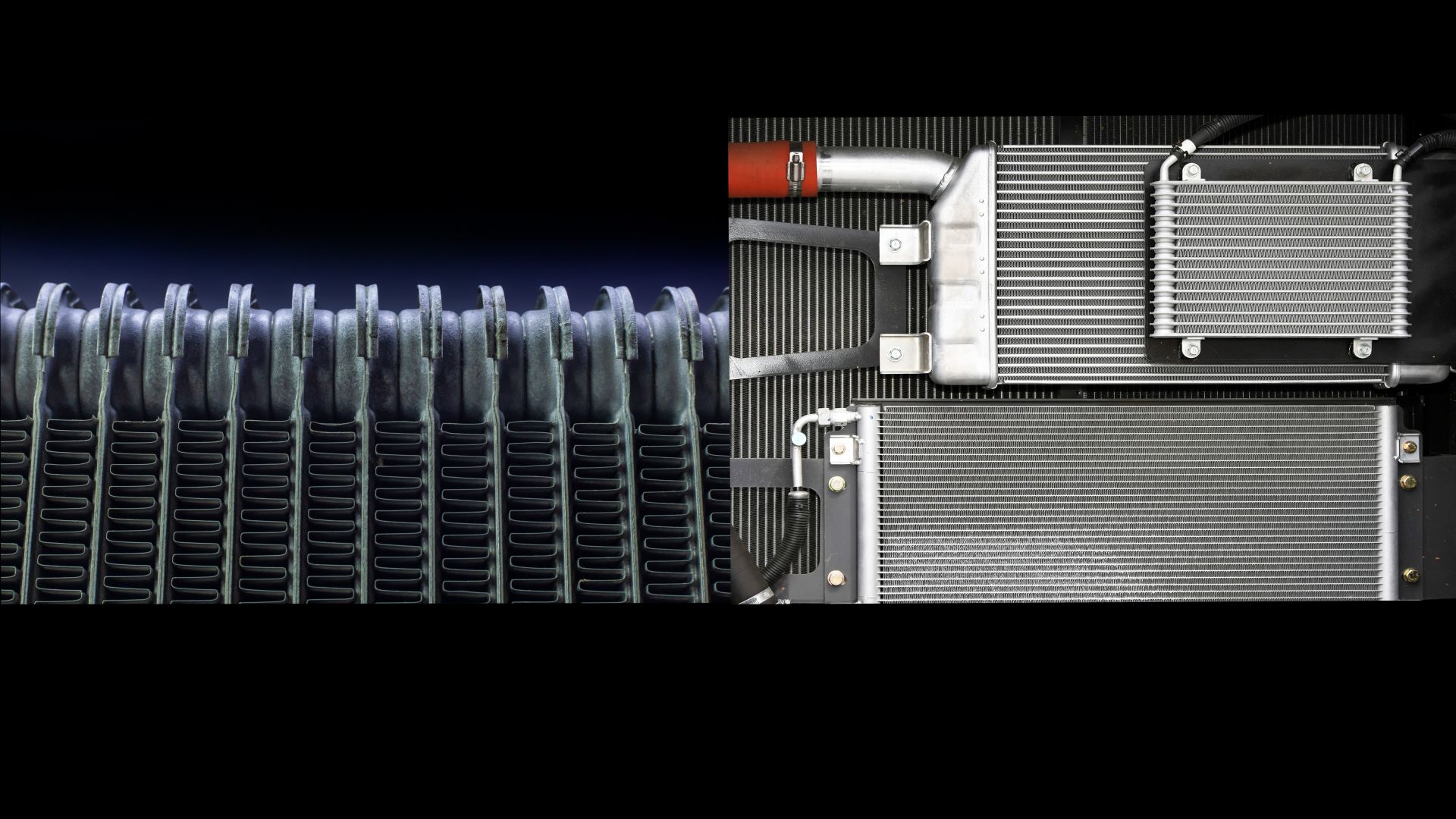

Paint protection for air conditioning and cooling